Equipment

Advanced Equipment for Solar Cell Research & Development

At Homerun Energy, we understand that the transition from innovative ideas to functional, high-performance solar technologies requires precision, reliability, and control at every step of the research and development process. That’s why we provide a comprehensive suite of state-of-the-art laboratory and pre-production equipment tailored to meet the demands of cutting-edge research in perovskite and dye-sensitized solar cell technologies.

Our equipment portfolio is built around the principles of consistency, reproducibility, and ease of integration into diverse research environments. Whether you’re developing new materials, optimizing device architecture, or preparing for scale-up, our solutions are designed to accelerate your workflow without compromising on quality or accuracy.

From programmable hotplates and precision sealing presses to advanced screen printers and light soaking chambers, each instrument is engineered to deliver exact control and dependable performance. We aim to empower scientists, engineers, and innovators by offering tools that allow them to focus on what truly matters: discovering new pathways to more efficient, stable, and commercially viable solar technologies.

Programmable Hotplate

The Programmable Hotplate delivers precise, reliable heat for curing and baking electrodes and substrates. With up to 32 customizable temperature steps, ramp timing, and high thermal uniformity, it ensures consistent results across every batch. Its durable nickel-plated surface and optional protective lid make it suitable for any research environment.

Key Specs:

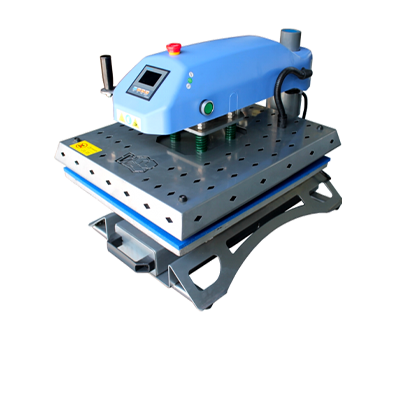

Pneumatic Heat Press

Designed for the rapid and consistent sealing of Perovskite and DSC test cells, the Pneumatic Heat Press applies uniform heat and pressure via a user-controlled system. It supports precision sealing using standard thermoplastic gaskets.

Key Specs:

Screen Printer

A versatile, semi-automatic screen printer for electrode, conductor, and paste applications. Designed with customizable squeegee speed, flood blade control, and alignment jigs, it provides repeatable, high-quality prints for any batch size.

Key Specs:

Ultrasonic Soldering Station

An advanced soldering tool that replaces flux with ultrasonic cavitation—ideal for clean, high-precision soldering on glass, ceramics, and metals. Its adjustable temperature and vibration output offer a flexible solution for delicate materials.

Key Specs:

Laser Scribing Machine

Our Laser Scriber enables precise removal of conductive oxide layers from glass or polymer substrates, allowing series connection layout. Compatible with user CAD files and featuring programmable controls.

Key Specs:

Certified Reference Cell

Ensure accurate light source calibration with our monocrystalline silicon reference cell. Ideal for indoor lab settings and compatible with PT100 temperature sensing.